Headspace analysis is a technique for sampling and examining the volatiles associated with a solid or liquid sample. The actual headspace itself is the volume of vapor or gas above the sample. For most headspace analysis purposes the sample and its associated headspace are held within an enclosed container (Figure 1 ).

The methods are for off-line or automated headspace microextraction under vacuum conditions, so that the extracting unit with analytes can be conveniently analyzed by means of an analytical instrumentation such as gas chromatography, gas chromatography-mass spectrometry, liquid chromatography, and/or liquid chromatography-mass spectrometry.

Dec 16, 2019 · When sampling the headspace vial should be pressured, using its pressure to the gas phase part (headspace phase) export of the small glass bottle method called the balance pressure method. As the best device, when the pressure of the separation system is balanced, the headspace phase is directed directly into the column for analysis.

a vial containing the sample, the dilution solvent, a matrix modifier, and the headspace (see Figure 1). Volatile components from complex sample mixtures can be extracted from non-volatile sample components and isolated in the headspace or vapor portion of a sample vial. An aliquot of the vapor in the headspace is delivered

Aug 01, 2000 · Two Headspace SPME methods were developed and optimized: one for the extraction from aqueous solutions, and the other for the extraction from organic solutions (N,N-dimethyl formamide (DMF) and dimethyl sulfoxide (DMSO). The optimum equilibration time for all components and all systems was 30 min.

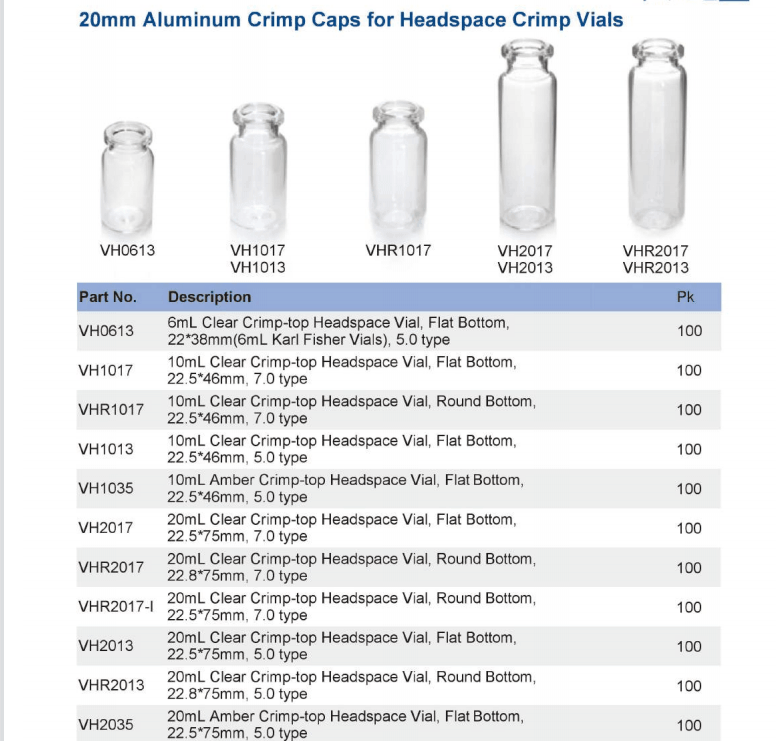

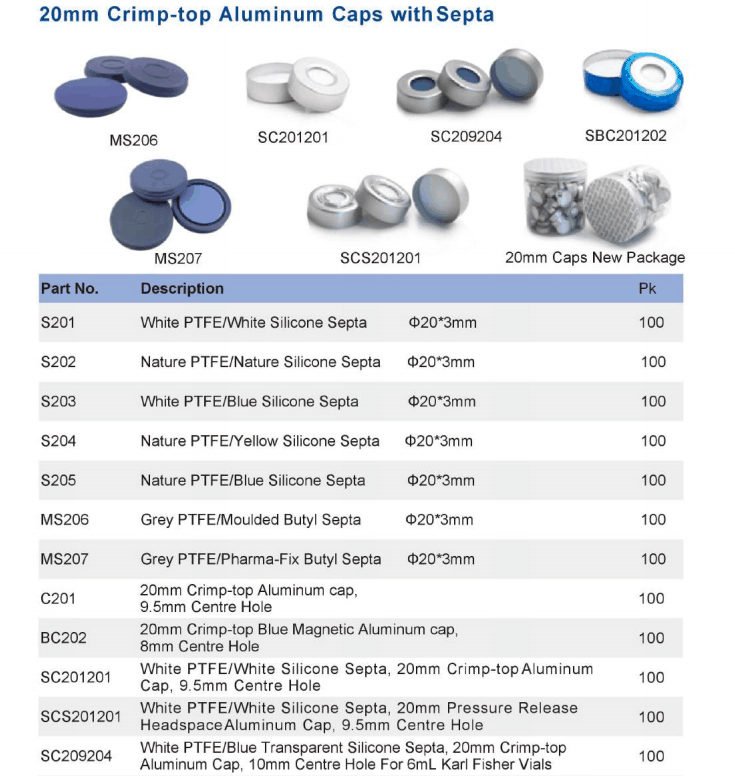

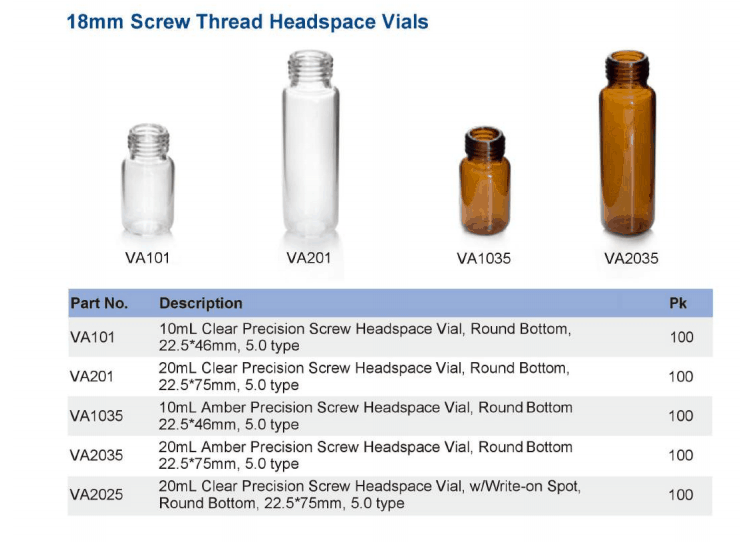

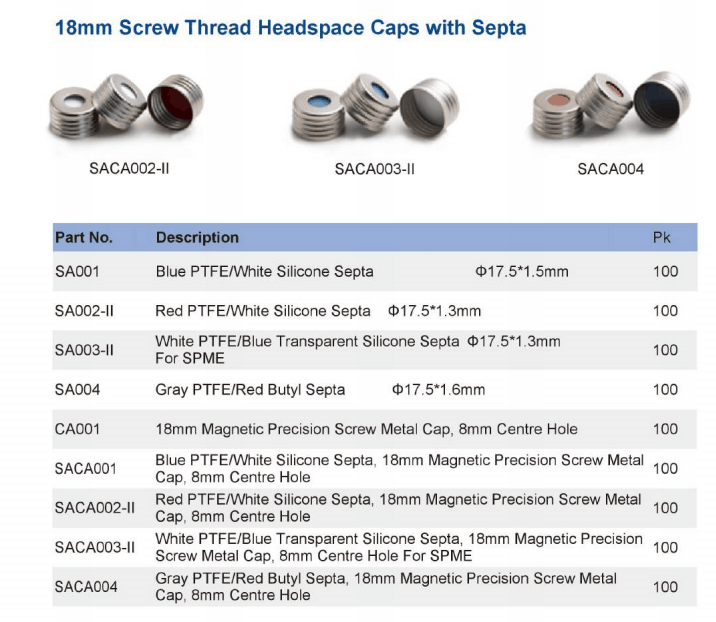

Headspace Vial. Headspace vial manufactured from Borosilicate glass by Aijiren. Headspace vial can be available in 6ml - 20ml. Clear or Amber can be choose. Screw Thread Headspace Vials use a 1.25 mm average wall thickness, which offers more reliability when internal pressures build. Our Headspace Vials meet or exceed OEM standards.

Abstract. A headspace gas chromatographic (GC) method, which can be automated, has been developed for determination of methyl bromide. This method has been applied to wheat, flour, cocoa, and peanuts. Samples to be analyzed are placed in headspace sample vials, water is added, and the vials are sealed with Teflon-lined septa.

Mar 16, 2022 · Article on Container Closure Integrity Test Method Development on Vials Stored at -80°C Using Headspace Carbon Dioxide Analysis, published in PDA Journal of Pharmaceutical Science and Technology on 2022-03-16 by Ken G Victor+2. Read the article Container Closure Integrity Test Method Development on Vials Stored at -80°C Using Headspace Carbon Dioxide Analysis on R Discovery, your go-to

Jan 17, 2020 · Specification of Headspace Vial. The Hawach headspace bottle with a diameter of 10 ml, 22.5ⅹ50 mm, 20 ml, 27.5ⅹ70 mm, which is currently the most commonly used gas-phase injection bottle on the market, and the threaded round-bottom bottle can be said to be an upgraded version of the clamp type, which ensures that it can achieve the original

The method is based on headspace sampling of a 2 ml vial containing 1 g of sample. For analysis, samples were spiked with d (4)-furan, homogenized in a blender at 0 degree C, with water if required, and sub-sampled to vials containing sodium sulphate. After equilibration at 30 degrees C, 50 microl of headspace was injected into the split

Jul 30, 2020 · The Effect of Vial Pressure, Loop Pressure, and Fill Rate. 15 psi vial pressure. 10 psi/min fill. 5 psi final pressure. 40 psi vial pressure. 30 psi/min fill. 10 psi final pressure. 40 psi vial pressure. 30 psi/min fill. 5 psi final pressure. 27 July 29, 2020 Head in the Right Direction with Headspace Anaysis DE.4178703704

Aug 08, 2019 · This first step is to immerse the whole empty vial into the alcohol of 95%, due to its compatibility with most organic solvents. Then dry it after washing it twice by ultrasound. Afterward, pour some clear water into the vial and continue to wash it by ultrasound for twice.

cat.#. 21160, 21161. The following instruments are compatible with the headspace vials listed in the ordering table. For further information or questions, please contact your Restek sales representative or technical service. Manufacturer. Instrument/Model #. 6 mL Vial. cat.# 21166 (100-pk.), 21167 (1,000-pk.) Carlo Erba.

Dec 17, 2019 · Dec. 17th, 2019. Headspace sample handling is a convenient and fast sample pretreatment method in gas chromatography. The principle is to place the sample to be tested in a closed container, by heating up the volatile components from the sample base to spread out, in the gas liquid (or gas solid) in both phases to achieve balance. Then direct

Aijiren headspace vials come in two basic sizes (10 mL glass vials and 20 mL glass vials; Crimp caps are most common however many customers use screw sample and application dependent; clear glass vials and amber vials are available; 11 mm caps, 18 mm caps, and 20 mm caps are engineered to prevent sample contamination while providing consistent, secure seals.

Material: USP Type 1, Class A, 33 Borosilicate Glass

Volume: 2ml (standard volume) 1.5ml(actual volume)

Application: HPLC and GC system

Dimensions: 11.6 x 32mm

Neck Diameter: 8mm

Qty/Pack: 100pcs/pack

Payment: T/T

MOQ: 1pack

Material: USP Type 1, Class A, 33 Borosilicate Glass

Volume: 2ml (standard volume) 1.5ml(actual volume)

Application: HPLC and GC system

Dimensions: 11.6 x 32mm

Neck Diameter: 9mm

Qty/Pack: 100pcs/pack

Payment: T/T

MOQ: 1pack

Material: USP Type 1, Class A, 33 Borosilicate Glass

Volume: 2ml (standard volume) 1.5ml(actual volume)

Application: HPLC and GC system

Dimensions: 11.6 x 32mm

Neck Diameter: 10mm

Qty/Pack: 100pcs/pack

Payment: T/T

MOQ: 1pack